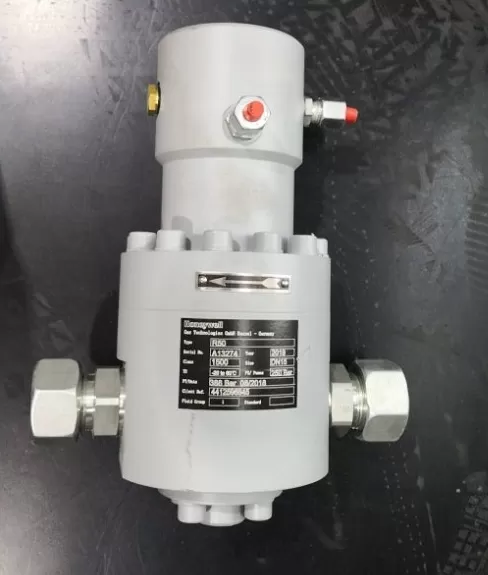

Honeywell _ Gorter regulador BAAI R50

Regulador de presión BAAI R50 Producto Specification

1. Producto Introduction

The El regulador de presión cargado con domo serie Gorter R50 es un regulador de alta presión con de gran adaptabilidad. Está diseñado para la clase de presión ANSI1500, con alta capacidad de flujo, alta confiabilidad y un amplio rango de presión de salida.

2. Tamaño técnico Parameters

ParameterDetails

Connection - Entrada / Salida BSP 1 "

Connection Tamaño - Suministro / Escape BSP 1 / 4"

Conexión de cuerpo de válvula y puerto DN1 / 2 "1" BSP

Minimum/ Temperatura máxima permitida (TS) - 20C / + 60C

Maximum Entrada y salida Pressure25MPa

Rated Flujo 2000Nm³ / h

3. Producto Features

3.1 Mantenimiento extremadamente bajo Cost

Long Ciclo de mantenimiento: Reduce la frecuencia del mantenimiento del cierre.

Fácil montaje y desmontaje: facilita la inspección y el reemplazo rápidos de componentes.

Patented El cuerpo de la válvula permite el mantenimiento en línea: permite el mantenimiento sin apagar el sistema, minimizando el tiempo de inactividad.

Inspección simple y conveniente del sello del asiento: permite la detección oportuna de problemas de sello.

Muy pocas piezas de repuesto para reparación: reduce los costos de inventario y compra.

Excelente volumen de la cámara de aire de control Performance

Large: contribuye a una regulación de presión estable.

Precisión de alta regulación (1%): Asegura un control de presión de salida preciso.

Baja presión de cierre (2,5%): Reduce las fluctuaciones de presión durante el apagado.

Respuesta rápida y buena estabilidad: se adapta rápidamente a los cambios de presión y mantiene un funcionamiento estable.

Amplio rango Seguridad y Reliability

Designed hasta 250 Kg de Presión Clase: Garantiza un funcionamiento seguro en condiciones de alta presión.

4. Trabajando Principle

Open la válvula de aguja de entrada del grupo de válvula de aguja superior (11) en la cavidad superior, permitiendo que el gas aguas arriba entre en la cavidad superior (10) a través de la válvula de aguja, aumentando la presión de carga en la cavidad superior, que actúa sobre el diafragma (5). De este modo, se aumenta la presión del juego de salida. La apertura de la válvula de aguja de salida del grupo de válvulas de aguja (11) permite que el gas en la cavidad superior se libere a través de la cavidad de baja presión de falla (10) para reducir el valor establecido de presión de salida. El uso combinado de las válvulas de aguja de entrada y salida puede lograr el propósito de establecer la presión de salida.